Industrial Fitting

Forged Pipe Fittings

Our stainless steel and carbon steel ANSI Forged Fittings are available for 2000lbs, 3000lbs, 6000lbs, 9000lbs Socket Weld as well as Threaded End - NPT, PT or other types, mainly in stainless steel 304/304L & 316/316L and carbon steel from 1/8" (DN6) up to 4" (DN100). Other various grades such as 304H, 309S, 309H, 310S, 310H, 316TI, 316H, 316LN, 317, 317L, 321, 321H, F11, F22, F91, 347, 347H, 904L are available too. In addition to this, our Pipe Fittings, Forged Fittings, Stainless Fittings, Steel Fittings, Elbow Fittings, Weld Fittings, High Pressure Fittings, Thread Fittings, socket weld, 3000 fitting are in compliance with the set industry standards like ASTM/ASME A/SA 182, ASTM/ASME A/SA 312, ASTM/ASME A/SA 403, ASTM/ASME A/SA 105, ASTM/ASME A/SA 350 LF2, ASTM/ASME A/SA 106, ASTM/ASME A/SA 234.

Moreover, we manufacture Pipe Fittings, Forged Fittings, Stainless Fittings, Steel Fittings, Elbow Fittings, Weld fittings, High Pressure Fittings, Thread Fittings, Socket Weld, 3000 Fitting in various types including Elbow 90, Elbow 45, Street Elbow, Tee, Union, Cross, Pipe Coupling, Half Coupling, Reducing Coupling, Pipe Cap, Hex. Head Bushing, Hex. Head Plug, Square Head Plug, Round Head Plug, Bull Plug, Welding Boss, Hexagon Nipple, Reducing Hexagon Nipple, Barrel Nipple, Welding Nipple, Swage Nipple, Pipe Nipple, Parallel Nipple, Hose Nipple, Hexagon Nut, Bend, Adapter, Insert, Outlet, Welding Outlet, Weldolet, Elbowolet, Socketolet, Threadolet, Nipolet and Letrolet. We also offer the value added services to our clients such as hot dip galvanizing sand blasting.

These Forged Pipe Fittings, are commonly used to change the direction in piping, thereby changing the direction of the water flow. Our entire range of forged stainless steel fittings, forged steel pipe fittings, forged alloy steel pipe fittings, thread and socket weld, 3000 fitting are appreciated for high durability, dimensional accuracy, smooth finish, leak proof and corrosion resistant features. The applications range from chemical, petro chemical, power generation and OEM manufacturing industry as well other applications where vibration, high pressure or extremely corrosive conditions exist. Socket weld material is significantly more popular then threaded since most applications call for completely sealing off a line and eliminating all possibility of leakage.

We are stainless steel manufacturer, carbon steel manufacturer, Fittings manufacturer, Taiwan manufacturer, Taiwan supplier and Taiwan factory because we are manufacturing in Taiwan our Forged Fittings, Stainless Fittings, Steel Fittings, Pipe Fittings, Elbow Fittings, Welding Fittings, High Pressure Fittings, Thread Fittings, Socket Weld, 3000 Fitting , which are all made in Taiwan. Welcome to buy from Taiwan our forged pipe fittings.

We are also China manufacturer, China supplier, China factory, China wholesale and China exporter because we are manufacturing in China our Forged Fittings, Stainless Fittings, Steel Fittings, Pipe Fittings, Elbow Fittings, Weld Fittings, High Pressure Fittings, Thread Fittings, Socket Weld, 3000 Fitting, which are made in China too. Also welcome to buy from China our pipe fittings.

Socket Weld Fittings

A Socket Weld is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange. In contrast to buttweld fittings, Socket Weld fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller.

To join pipe to Valves and fittings or to other sections of pipe, fillet-type seal welds be used. Socket Welded Joints construction is a good choice wherever the benefits of high leakage integrity and great structural strength are important design considerations.

Fatigue resistance is lower than that in butt-welded construction due to the use of fillet welds and abrupt fitting geometry, but it is still better than that of most mechanical joining methods.

Some details of Socket Weld fittings

SW Fittings are family of high pressure fittings are used in various industrial processes.They are used for lines conveying flammable, toxic or expensive material where no leakage can be permitted, and for steam 300 to 600 PSI.

They are used only in conjunction with ASME Pipe and are available in the same size range.

They are used in areas where pipe-work is permanent and are designed to provide good flow characteristics.

They are are produced to several ASTM standards and are manufactured in accordance with ASME B16.11. The B16.11 standard covers pressure-temperature ratings, dimensions, tolerances, marking, and material requirements for forged carbon and alloy steel. Acceptable material forms are forgings, bars, seamless pipe, and seamless tubes which conform to the fittings chemical requirements, melting practices, and mechanical property requirements of ASTM A105, A182, or A350.

They are available in three pressure ratings.. Class 3000, 6000 and 9000.

THREAD FITTINGS

We manufacture and export threaded fittings that exhibit superior functioning. These threaded pipe fittings are designed & developed to meet diverse working conditions. These threaded fittings provide permanent welded connections for critical applications. Threaded joints probably represent the oldest method of joining piping systems. Like Socket Weld fittings, threaded fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal

diameter is NPS 2 or smaller. The dimensional standards for taper pipe threads are given in ASME B1.20.1. That document gives all required dimensions including number of threads per inch, pitch diameter, and normal engagement lengths for all pipe diameters.

Threaded piping is commonly used in low-cost, noncritical applications such as domestic water, fire protection, and industrial cooling water systems.

Threaded piping is commonly used in low-cost, noncritical applications such as domestic water, fire protection, and industrial cooling water systems.

Threaded fittings are normally made of cast gray or malleable iron, cast brass or bronze, or forged alloy and carbon steel.

They are available in three pressure ratings: 2000lbs, 3000lbs and 6000lbs.

Enquiry Now

They are available in three pressure ratings: 2000lbs, 3000lbs and 6000lbs.

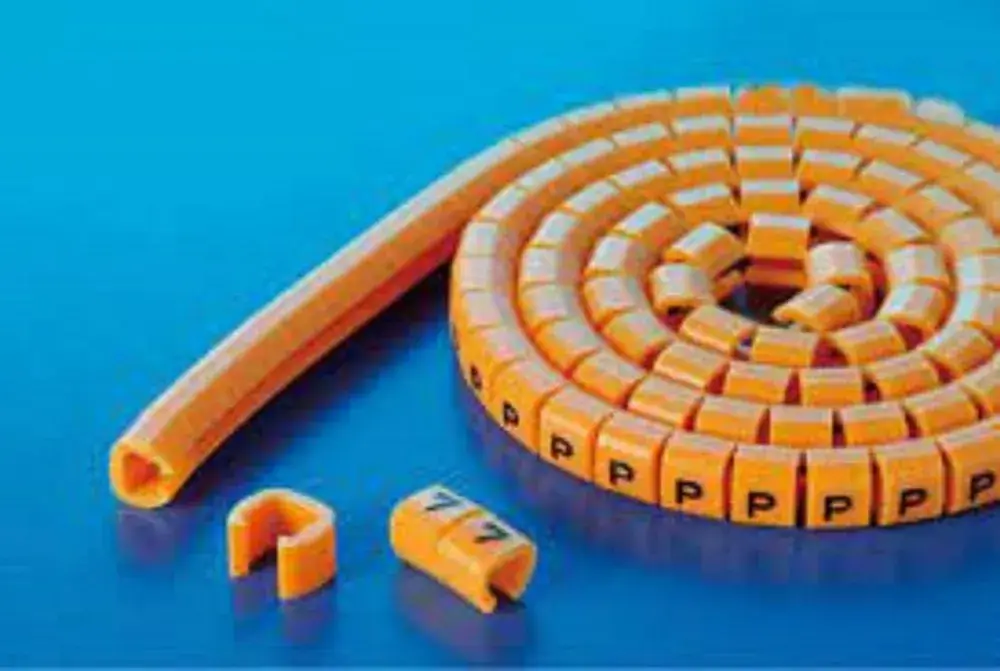

Cable Ferrules

Cable Ferrules with letter print are for label use. Easy to pass through as flexible cable type. Organize the tangled mess cables behind your computer desk for convenient use. You can also use them to identify anything you would like to easily tag. One of the most convenient advantages these Cable IDs offer is the ease of installation. Just slip an ID around a cable. You can use them on cables before fixing connectors.

Used in Marking-up Wires & Cables. Trader and supplier of an impeccable array of Electrical Products and Hardware Products. These are recognized for durability and high strength.

Enquiry Now

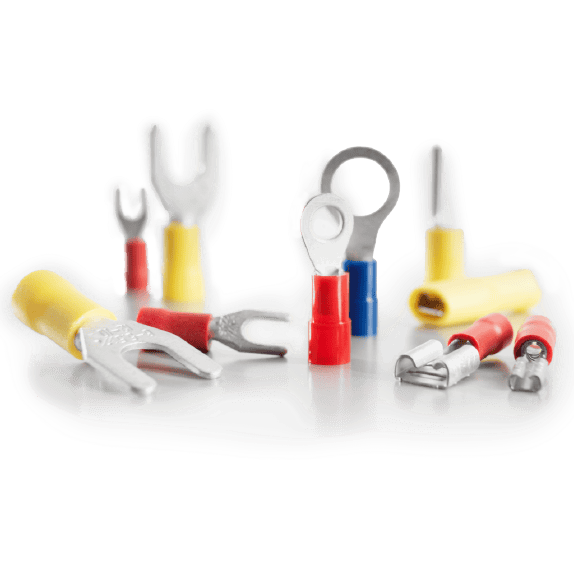

Cable Lugs

The complete range of electrical connectors for jointing and terminating cables and connecting conductors into low, medium and high voltage switchgear, control panels and transformers using compression (crimping) or mechanical shearbolt (“snap-off”) type connectors.

Connectors are available to lug, crimp and splice cables for LV, MV and HV applications with copper or aluminium conductors ranging from 1.5sqmm up to 1200sqmm.

Compatible with 11kV and 33kV cold shrink, heat shrink, push-on and slip-on type cable joints and cable terminations – crimp, shearbolt and brass tunnel type connectors suit for resin cable joints.

- Low Voltage 600/1000 Volts (3.3kV)

- Medium Voltage 6.6kV 11kV 33kV

- igh Voltage 66kV 72kV

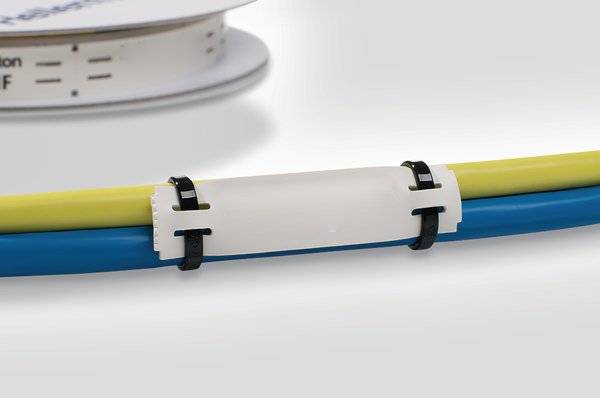

Cable Tags

Although they may be used to identify single cables, cable tags are most often used to identify bundles of cables. A cable tag is typically attached to a cable bundle using the same plastic tie-wrap that holds a bundle of cables together.

Cables may be bundled together based on their function so as to keep various types of cabling separated. In addition, bundling cables and securing them with ties helps to stabilize the cables. Cable tags then are used to identify bundles of power cables, grounding wires, a/v cables, telecommunications and data center cabling.

Cable tags should be made using a thermal transfer printer and be never hand printed. Thermal transfer printing ensures the cable tags will be legible and durable. In addition, with thermal transfer printing templates can be created to ensure standard tag formats are used, increasing the ability of the tag to clearly and effectively communicate the needed information.

Enquiry Now